Centralized web-portal of industrial equipment for digital passportization and product life cycle monitoring using RFID and NFC identification

Main possibilities of the service are transferring and management of equipment data (operation of the product before selling or leasing, technical characteristics and its specifications, forecasting replacing, repair and maintenance in time, as well as searching for a supplier, for example, of spare parts).

Attaching a tag with unique ID to the equipment to create the corresponding item in Go-Base system and transfer technical documentation to customer

Unified service of digital passportization and technical control of industrial equipment

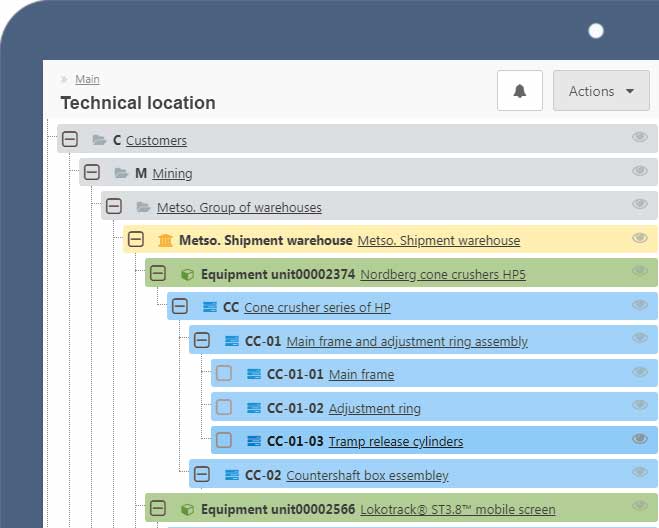

Centralized database of current information of the equipment in use

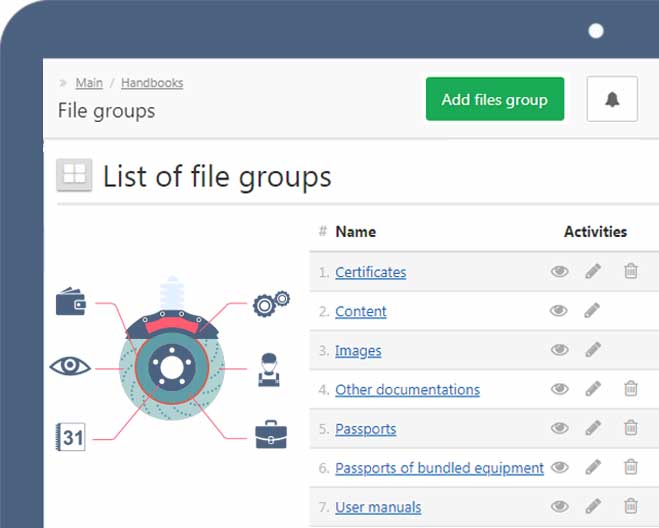

Centralized online-portal for storage and processing operational equipment documentation

Hardware and software system for identification, data analysis and management

Step by step review of work principals of Go-Base system, its tools and main participants

1 Manufacturer

he task is to provide direct connection with consumer and to establish quick document flow of engineering objects. This will help to avoid counterfeit products, identify possible causes of failure or crash of equipment, while forecasting its technical condition and increasing quality management level.

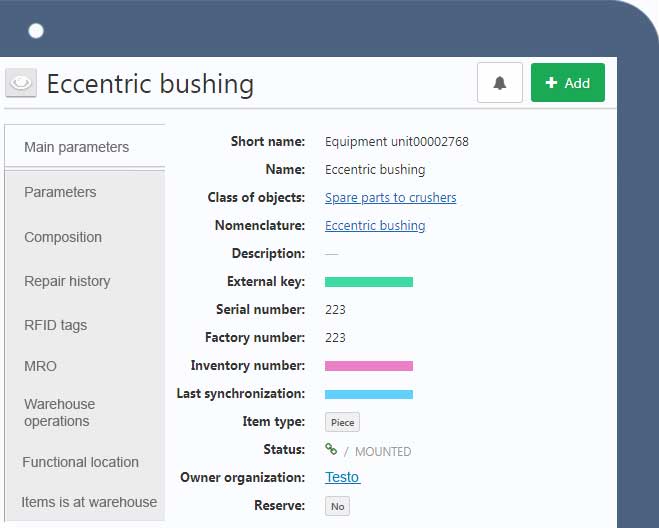

2 Digital passport

The manufacturer sends unique technical passport for each equipment unit through Go-RFID system of accounting and identification or directly to Go-Base through API, integrating with the enterprises' data management system.

3 Tagging of equipment

Then items corresponding to each transmitted product passport are created in manufacturer's account for further tagging and identification.

4 Synchronization

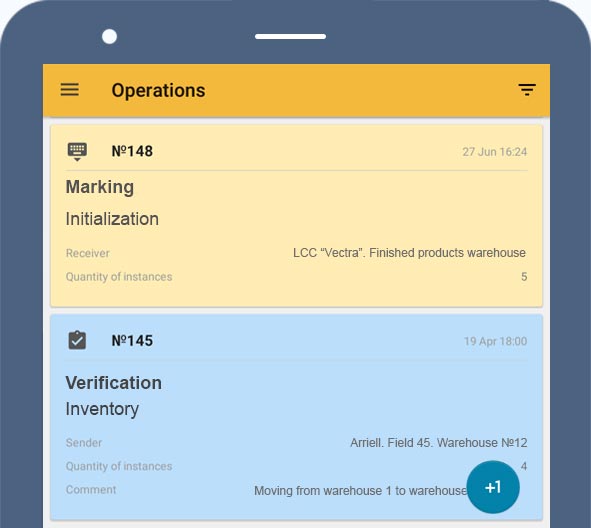

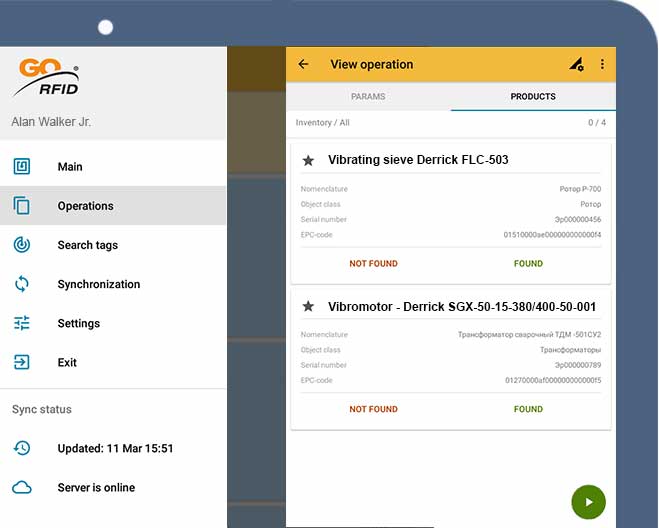

RFID-tag with unique ID is attached to each product which is automatically registered in the system through Go-RFID Mobile application using industrial Android tablet or mobile reader.

5 Data uploading to Go-Base

Then with each read, the application determines the tag ID which identifies the serial number of equipment and displays personal information for particular item.

6 Access to information

RFID tag remains on the body of the equipment throughout the entire life cycle of product item during exploitation. This creates a working online space for quick exchange of reliable documentation from manufacturer and customer's and suppliers interaction.

Autonomously manage access to a single data store on manufactured products

Track product status at each stage of life cycle

Reduce the percentage of emergency outages at the place of production and field

Create unique digital passports for each item of equipment

Automate the process of storing, managing and accounting information about equipment on a single platform